Common Oil Burner Problems in Long Island

When dealing with oil furnace issues, we encounter a range of problems that may impact the system’s efficiency and functionality. It’s important to approach these issues methodically to diagnose and fix them effectively. Below, we’ve outlined some of the common problems you may face with your oil furnace:

- No Heat: This could stem from a variety of causes, such as a tripped circuit breaker, a malfunctioning thermostat, or a clogged fuel line. A visual inspection can often reveal if the problem is something simple like a filter needing replacement.

- Strange Odors: A well-functioning furnace should not emit strong odors; if you notice a smell similar to fuel oil, it may indicate incomplete combustion or an oil leak. It’s essential to address these odors promptly.

- Unusual Sounds: Knocking, rumbling, or whistling sounds can be a sign that air is trapped in the lines, or there may be an issue with the burners or blower motor.

We suggest creating a troubleshooting checklist of these common issues:

| Problem | Possible Causes | Suggestions for Troubleshooting |

|---|---|---|

| No Heat | Tripped breaker, thermostat, clogged line | Check power supply, inspect filter |

| Strange Odors | Oil leak, incomplete combustion | Inspect for leaks, ensure proper combustion |

| Unusual Sounds | Air in lines, burner/blower motor issues | Bleed lines, inspect motor and burners |

| Frequent Cycling | Poorly calibrated thermostat, faulty controls | Calibrate thermostat, inspect controls |

| Increased Fuel Consumption | Inefficient operation, leaks | Check for leaks, service as necessary |

- Frequent Cycling: If the furnace turns on and off more frequently, it could be due to an incorrectly calibrated thermostat or faulty control board.

- Increased Fuel Consumption: Should you notice a spike in fuel use, it might indicate inefficient furnace operation or an underlying leak in the system.

We recommend a visual inspection to examine external components for signs of wear or damage, and professional servicing for internal issues. Remember, safety comes first, and if you’re unsure about a problem, it’s best to consult with a qualified technician.

Regular Maintenance and Inspection

We recognize that proper maintenance is crucial for the longevity and efficiency of oil burners. Our focus on regular maintenance and inspection ensures that every component functions optimally, from filters to burners.

Cleaning and Replacing Filters

Regular cleaning and replacement of air filters are essential to maintain air quality and proper airflow within the system. We recommend inspecting air filters monthly and replacing them as needed. A clogged air filter can restrict airflow, forcing the oil burner to work harder, which may lead to increased wear and reduced efficiency.

- Visual Inspection: Check for dust and debris buildup.

- Replacement: If the filter is noticeably dirty or has been in use for more than three months, replace it to maintain ideal performance.

Inspecting and Maintaining Burners

The oil burner requires periodic inspections to ensure it is in good working condition. We carry out a visual inspection to assess the state of the burner and identify any signs of wear or malfunction.

- Visual Inspection: Look for soot, corrosion, or damage on the burner assembly.

- Cleaning: Use a vacuum or a small brush to remove any debris from the burner assembly. Ensure the nozzle and electrodes are clean to prevent ignition problems.

Regular maintenance of the burners and ductwork can prevent common issues such as poor heating performance and system failures. Our maintenance routine keeps your system running efficiently and reliably.

Troubleshooting Common Issues

When we approach common oil burner issues, it’s essential to check system settings, ensure proper power supply, and assess the condition of key components such as the thermostat and fuel supply. Careful troubleshooting can address most problems without the need for professional intervention.

Resetting the System and Checking Power Supply

Before we delve deeper into complex issues, we always start with the basics. If the oil burner is not starting or there’s no heat:

- Press the reset button on the burner or the reset switch on the motor. Do this only once; multiple resets can flood the burner.

- Check the power supply to the furnace. Ensure that the switch controlling the furnace is set to “On.”

- Look for a tripped circuit breaker or a blown fuse in the electrical panel. If we find any tripped circuit breakers, we reset them. If we find blown fuses, we replace them with ones of the same rating.

Addressing Thermostat and Circuit Breaker Issues

Thermostat and electrical issues are common culprits when there’s no heat:

- Thermostat setting: Verify that it’s set above the current room temperature and to “heat” mode.

- Circuit breakers: If problems continue after resetting the circuit breaker, we inspect for any exposed or damaged wires that might cause repeated trips.

Handling Fuel Supply and Oil Leaks

Ensuring an adequate fuel supply and addressing leaks is crucial:

- Oil tank: We confirm there’s enough oil in the tank to prevent low-fuel issues affecting the burner operation.

- Oil filter and oil pump pressure: Regularly checking and replacing the oil filter is key as a clogged filter can hinder fuel flow. Oil pump pressure must be adjusted to manufacturer specifications.

- Oil leaks: If we notice oil leaks, especially near the nozzle adapter or oil lines, we rectify them immediately to prevent fire hazards and maintain optimal burner performance.

- Flue pipe: A clear flue pipe is necessary for safe operation, so we inspect it for obstructions that can affect flame quality and lead to fuel consumption inefficiencies.

By meticulously following these troubleshooting steps, we can resolve common oil burner issues, restore heat quickly, and ensure an efficiently running furnace.

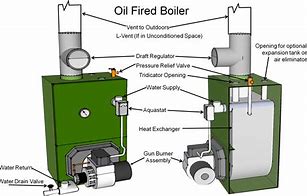

Technical Aspects and Component Failures

We’ll explore several critical components of oil furnaces, focusing on common issues that may occur and how to troubleshoot them. Our understanding of the technical aspects and components will guide us in maintaining efficient and safe operation.

Investigating Burner Nozzle and Electrodes

Burner Nozzle: The burner nozzle is vital for the proper atomization of fuel oil. A clog or wear can drastically affect performance, resulting in an incomplete combustion or no heat being produced. Regular inspection is essential, replacing the nozzle if damage or blockage is detected.

Electrodes: Positioned near the nozzle, electrodes generate the spark required for ignition. Misaligned or dirty electrodes might prevent the burner from igniting. It is crucial to check the gap and cleanliness of the electrodes, fine-tuning their position for optimal performance.

Examining Blower Motor and Belt Issues

Blower Motor: An oil furnace’s blower motor drives the fan that circulates air throughout the system. Symptoms of a failing motor include unusual noises or a failure to start, potentially due to overheating or worn bearings. Ensure the motor receives proper maintenance and replace if necessary.

Belt: A blower belt in poor condition may slip or break, leading to inadequate air circulation and reduced heating efficiency. Inspect the belt for signs of wear or cracking, tightening or replacing it as required to maintain effective operation.

Assessing Heat Exchanger and Flue Pipe Function

Heat Exchanger: The heart of an oil burner, the heat exchanger, transfers heat to air circulating through the HVAC system. Cracks or leaks in the heat exchanger can lead to dangerous carbon monoxide leakage. Inspect for signs of distress, ensuring it remains in good condition for safety and efficiency.

Flue Pipe: Exhaust gases from combustion are vented through the flue pipe. Obstructions or corrosion within the flue can lead to poor venting and backdrafts, which are hazardous. Regularly check the flue pipe’s integrity and clear any obstructions to secure a proper exhaust pathway.

Professional Help and Advanced Diagnostics

When oil-fired heating systems exhibit continuous problems, it’s prudent for homeowners to seek professional help. An HVAC technician or contractor specializes in complex diagnostics that go beyond the typical homeowner’s expertise. We understand that your comfortable home depends on a fully functional heating system, and we’re here to ensure that any disruptions are handled properly.

When to Call a Professional

- Unresolved recurring issues

- Emergencies such as oil leaks

- When beyond personal technical know-how

What is the average cost of the boiler repairs In Long Island

According to NORA Annual Boiler maintenance including the tune up costs as well as emergency repairs can cost between $500 – $800.

at Domino Fuel we serve most Long Island towns.

631 779 2716

Specialist Diagnosis Tools

Professionals use advanced test equipment to accurately diagnose issues with oil burners, boilers, and oil heating systems. Some tools used by professionals include:

- Flue gas analyzers: To check combustion efficiency

- Vacuum gauges: For oil pump pressure diagnostics

- Electronic ignitor testers: To troubleshoot ignition problems

Benefits of Hiring a Professional

- Safety: HVAC contractors are trained to handle hazards.

- Expertise: Technicians bring knowledge of the latest codes and best practices.

- Efficiency: Professionals diagnose and rectify problems swiftly.

- Warranty: Repairs by licensed technicians may protect manufacturer warranties.

Our focus is on providing the best path to restore your oil furnace. We encourage homeowners to consult with professionals who are experienced in furnace repairs to ensure their systems function optimally and their living environment remains comfortable. By employing professional diagnostics and repair services, we aim to minimize downtime and maximize the performance and longevity of your heating system.

Frequently Asked Questions

In our experience, many common issues related to oil furnaces can be diagnosed and often resolved with some troubleshooting. We’ve compiled a list of frequent problems and steps you can take to address them.

How can I troubleshoot an oil furnace that doesn’t ignite?

If your oil furnace fails to ignite, first ensure that there is oil in the tank and the valve is open. Check the thermostat and make sure it’s set to heat and above the current room temperature. Examine the circuit breaker and reset the furnace switch.

What steps should I follow if my oil burner fires up then stops after a short while?

Check the flame sensor or cad cell for dirt and clean it. Inspect the oil nozzle for clogs or damage, and replace if necessary. Ensure the air intake isn’t blocked and the flue isn’t obstructed. Sometimes, the problem might also be a defective thermostat or control box which would require professional servicing.

Why isn’t my heating system responding when the thermostat is adjusted?

Verify the thermostat is on the correct setting and functioning properly; replacing the batteries if it’s battery-operated. Check if the furnace switch is on and examine the circuit breaker for any tripped circuits. If these do not resolve the issue, there could be a fault with the furnace control board which would need professional attention.

What could be the reasons for my oil burner not firing up and possibly having an airlock?

The oil burner not firing up could be due to a lack of oil or an airlock in the fuel line. Bleeding the line may resolve the airlock. If the oil levels are sufficient, it might also be worth checking the filters and lines for blockage or damage.

How do I reset an oil burner when the reset button appears to be not functioning?

Attempt to reset the oil burner only once; multiple attempts can flood the chamber. If the reset button doesn’t work, investigate whether there is power to the furnace. If there’s power and the system is still unresponsive, the issue may involve the control box or the reset mechanism itself, requiring professional repair.

What are the common solutions for a non-heating oil furnace?

Ensuring the oil tank is filled and there’s power to the furnace are preliminary checks. A non-heating furnace may also result from a dirty filter, nozzle, or blower which can hinder operation. Regular maintenance is key; have the system serviced by a professional to address any issues with components like the oil pump or ductwork.